Sewer appurtenances

Sewer appurtenances are structures that are constructed at suitable intervals along a sewerage system to assist in efficient operation and maintenance. They include:- Manholes

- Drop manholes

- Lampholes

- Clean-outs

- Street inlets (called gullies)

- Catch basins

- Flushing tanks

- Grease and oil traps

- Inverted siphons

- Storm regulators

Manholes are masonry or R.C.C structures that are constructed at suitable intervals along sewer lines to provide access into them.

- Manholes help in joining sewer lengths

- Manholes also help in inspecting, cleaning and maintenance of sewers

- Perforated manholes also assist in ventilating sewers. However, they also cause evolution of pungent gases

- Manholes are generally provided at regular intervals in a straight sewer line. However, they are also provided at:

- every bend

- junction

- change of gradient

- change of diameter of sewer

- Spacing between manholes depends on size of sewer line

- Sewers with larger diameter will have manholes with greater spacing than those with smaller diameter

- Manholes are classified as :

- shallow manhole if it is 0.7 to 0.9 m in depth

- normal or medium manhole if it is 1.5 m deep

- deep manhole if it is more than 1.5 m deep

- A typical manhole consists of:

- Access shaft which is the upper portion of a deep manhole

- Working chamber that provides working space for inspecting and cleaning operations

- Benching or bottom invert portion of a manhole which is made of cement concrete. A semi-circular or U-shaped channel is constructed that allows the entry of sewage into the main sewer

- The side walls of the manhole are made of brick or stone masonry or R.C.C

- Steps or ladders are provided for descending into the manhole. The steps are made of cast iron and are places staggered at a horizontal distance of about 20 cm and a vertical center to center distance of 30 cm. The steps are fully embedded in the wall. Ladder is provided for deeper manholes. Steps or ladder start from 40 cm below ground level and continue up to 30 cm above the bottom level of the manhole

- The manhole is provided with a cast iron cover and cast iron frame at the top which is firmly embedded in the pavement. The top surface of the cover is roughened to avoid people from slipping while walking over it. An arrow mark over the top surface indicates the direction of flow of sewage.

Drop manholes

If a branch sewer enters a manhole by more than 0.5 to 0.6 m above the main sewer, the sewage is brought down through a down pipe taken from the branch sewer to the bottom of the manhole. If the drop is very small, a pipe sloping 45 to the ground is used, otherwise a vertical pipe is used as it is more economical. The manhole in which a vertical pipe is used (as shown) is called a drop manhole. If an inclined pipe is used, it is called a ramp.

- to avoid steep gradients and thus avoid earthwork excavation

- to avoid sewage trickling into the manhole from falling directly on the people working inside

Lampholes

Lampholes are small openings on sewers to permit the insertion of a lamp into the sewer. The lamp light is then viewed from the upstream as well as downstream manholes. Obstructed light confirms the obstruction in sewers. Lampholes are especially adopted when:

- a bend in sewer is necessary

- construction of manholes is difficult

- spacing between manholes is more than what is normally recommended

Clean-outs

A clean-out is an inclined pipe extending from the ground and connected to the under-ground sewer. It is used for cleaning sewer pipes. A clean-out is generally provided at the upper ends of lateral sewers in place of manholes.

A clean-out functions by removing the top cover and forcing water through the clean-out pipe to lateral sewers to remove obstacles in the sewer line. If the obstacles are large, a flexible rod may be inserted through the clean-out pipe and pushed forward and backward repeatedly to remove such obstacles

Street inlets

These are openings on the road surface at the lowest point for draining rain water from roads and allowing it to enter underground stormwater drains or combined sewers. Hence these inlets are located along road sides on straight roads at an interval of 30 m or 60 m. At intersection points they are located as shown. The inlets are placed in such a way that cross walks are not flooded. A street inlet is a simple concrete box having gratings or openings is known as vertical inlet or curb inlet. Inlet having horizontal openings is known as horizontal inlet.

Catch-basins

Catch basins are street inlets provided with additional small settling basins for grit, sand, debris to settle in the basin thereby preventing their entry in the sewer.

Street inlets

These are openings on the road surface at the lowest point for draining rain water from roads and allowing it to enter underground stormwater drains or combined sewers. Hence these inlets are located along road sides on straight roads at an interval of 30 m or 60 m. At intersection points they are located as shown. The inlets are placed in such a way that cross walks are not flooded. A street inlet is a simple concrete box having gratings or openings is known as vertical inlet or curb inlet. Inlet having horizontal openings is known as horizontal inlet.

Catch-basins

Catch basins are street inlets provided with additional small settling basins for grit, sand, debris to settle in the basin thereby preventing their entry in the sewer.

These basins need periodic cleaning otherwise, decomposition of settled organic matter may produce foul odour and become a breeding place for mosquitoes. Catch basins were considered necessary in old combined sewerage systems. However, in the modern days they are not considered essential

Flushing tanks

In case of blockage of sewer pipes in case they are laid at flat gradients and not producing self-cleansing velocities or at dead-end points of sewers, flushing devices are installed. These devices store water temporarily and discharge it rapidly into the sewer for the purpose of flushing and cleaning the sewer. Such devices are called flushing tanks.

Flushing tanks should store enough water for cleaning the sewer line. This capacity is generally kept equal to about one-tenth the cubic content of the sewer line served by it. The two types of flushing operations normally used are:

- Flushing operation using automatic flushing tank and

- Hand operated flushing operation

The automatic type of flushing tanks are used commonly nowadays.

Grease and oil traps

Grease and oil traps are trap chambers that are constructed in a sewerage system to remove oil and grease from the sewage before it enters the sewer line. Such traps are located near the sources contributing grease and oil to the sewage. They are generally located at places such as automobile repair work-shops, garages, kitchens of hotels, oil and grease industries etc.Removal of oil and grease from the sewage before it enters into the sewage pipe is considered necessary because:

- Oil and grease, if allowed to enter the sewer, sticks to the sewer sides thus reducing the sewer capacity.

- Suspended matter which would have flown along with the sewage, sticks to the side of the sewer due to sticky nature of oil and grease further reduces the sewer capacity

- Presence of oil and grease in the sewage adds to the possibility of explosion in the sewer.

- The presence of oil and grease in the sewage makes the sewage treatment difficult as their presence adversely affects the biochemical reactions.

The principle on which oil and grease are separated from water is that oil and grease being lighter than water float on the top surface of the sewage. The outlet is arranged such that it draws sewage from a lower level thereby excluding oil and grease at the top. These traps should be cleaned periodically.

Inverted siphons

If a sewer line is dropped below the hydraulic gradient line in order to pass under a valley, road, railway, stream, tidal estuary or any other depression under the Earth's surface, it is known as an inverted siphon or depressed sewer or sag pipe. The sewer in such cases will not flow under gravity but under pressure. An inverted siphon is thus a sewer section constructed lower than the adjacent sewer sections and it runs full under gravity and with pressure greater than the atmosphere.

An inverted siphon is usually made of siphon tubes or pipes made of cast iron or concrete. Pipes are normally laid between inlet and outlet chambers at the same elevation. The pipes between these ends are depressed for passing between obstructions. The inverted siphon laid between the inlet and outlet chambers consists of two sloping pipe lengths joined by a flat pipe length as shown.

Storm regulators

Storm water regulators are constructed in the combined sewerage systems and permit the diversion of excess storm water into a nearby stream.

Storm regulators

Storm water regulators are constructed in the combined sewerage systems and permit the diversion of excess storm water into a nearby stream.

Storm water regulators are of three types:

- Leaping weir

- Overflow weir

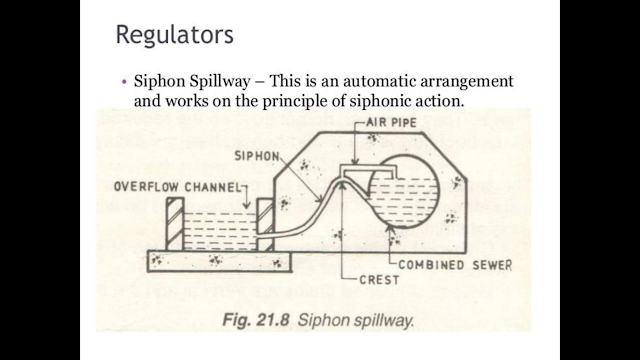

- Siphon spillway

nice info about sewage system

ReplyDelete